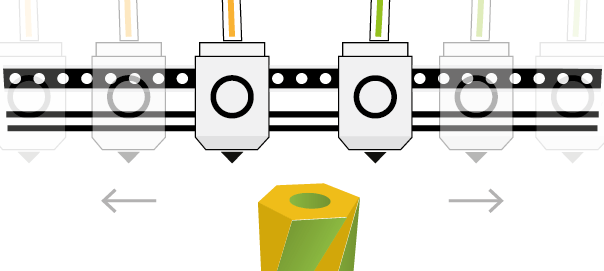

Fast yet detailed

Print up to three times faster without giving up quality: finer outlines and coarser infills.

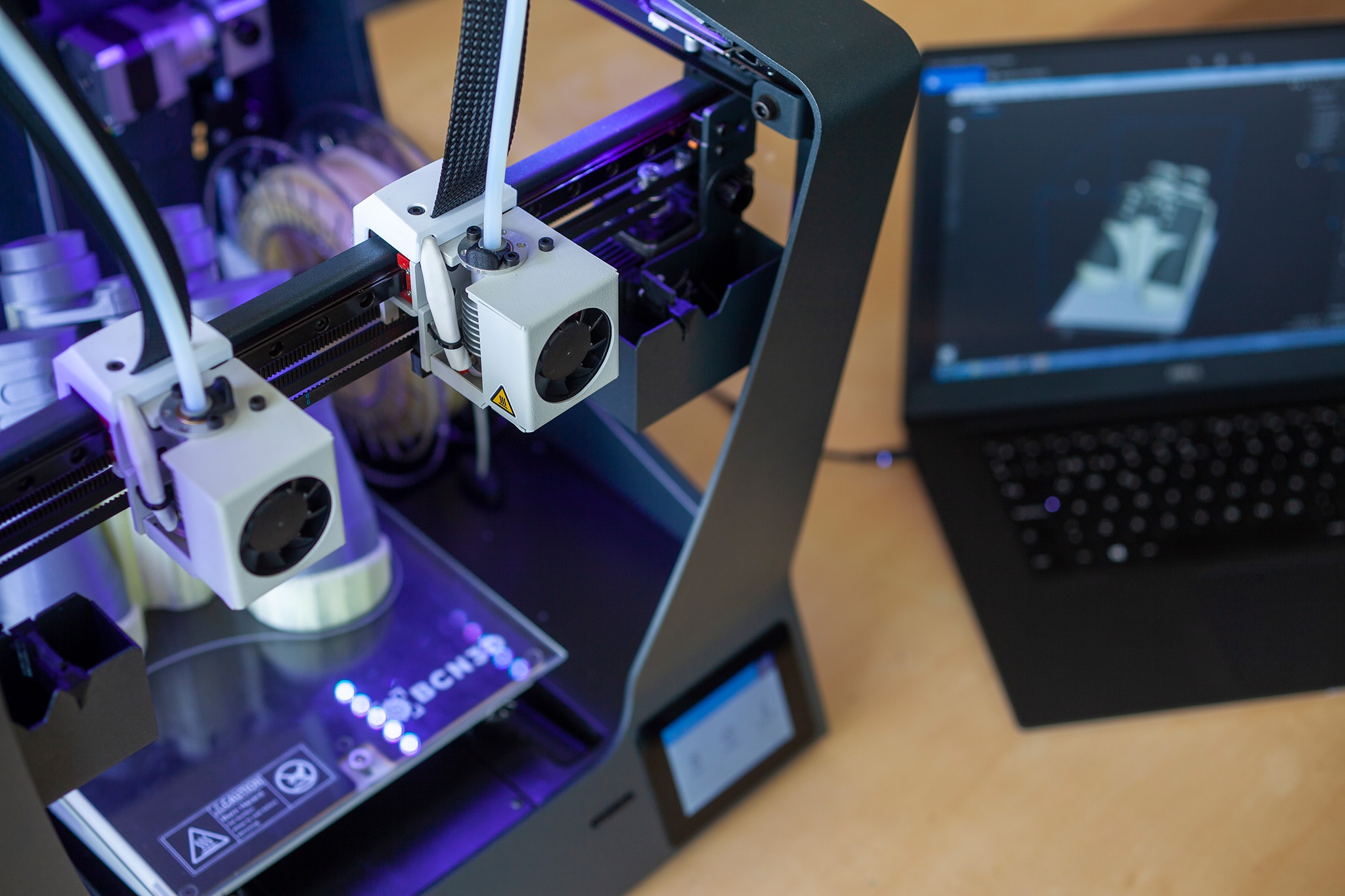

Quiet like a breeze

Reengineered cooling strategies allow to keep up the performance while reduce drastically the operating sound. Put a Sigma on your desktop!

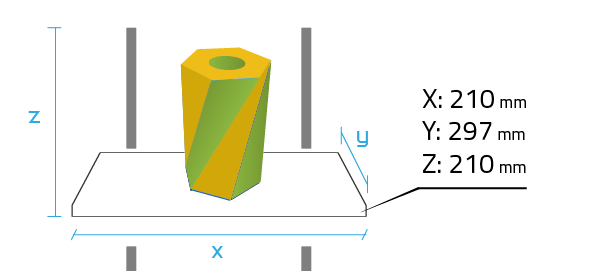

Accuracy redefined

Redesigned stepper drivers and improved power management set a new milestone in the accuracy of FFF 3D printers.

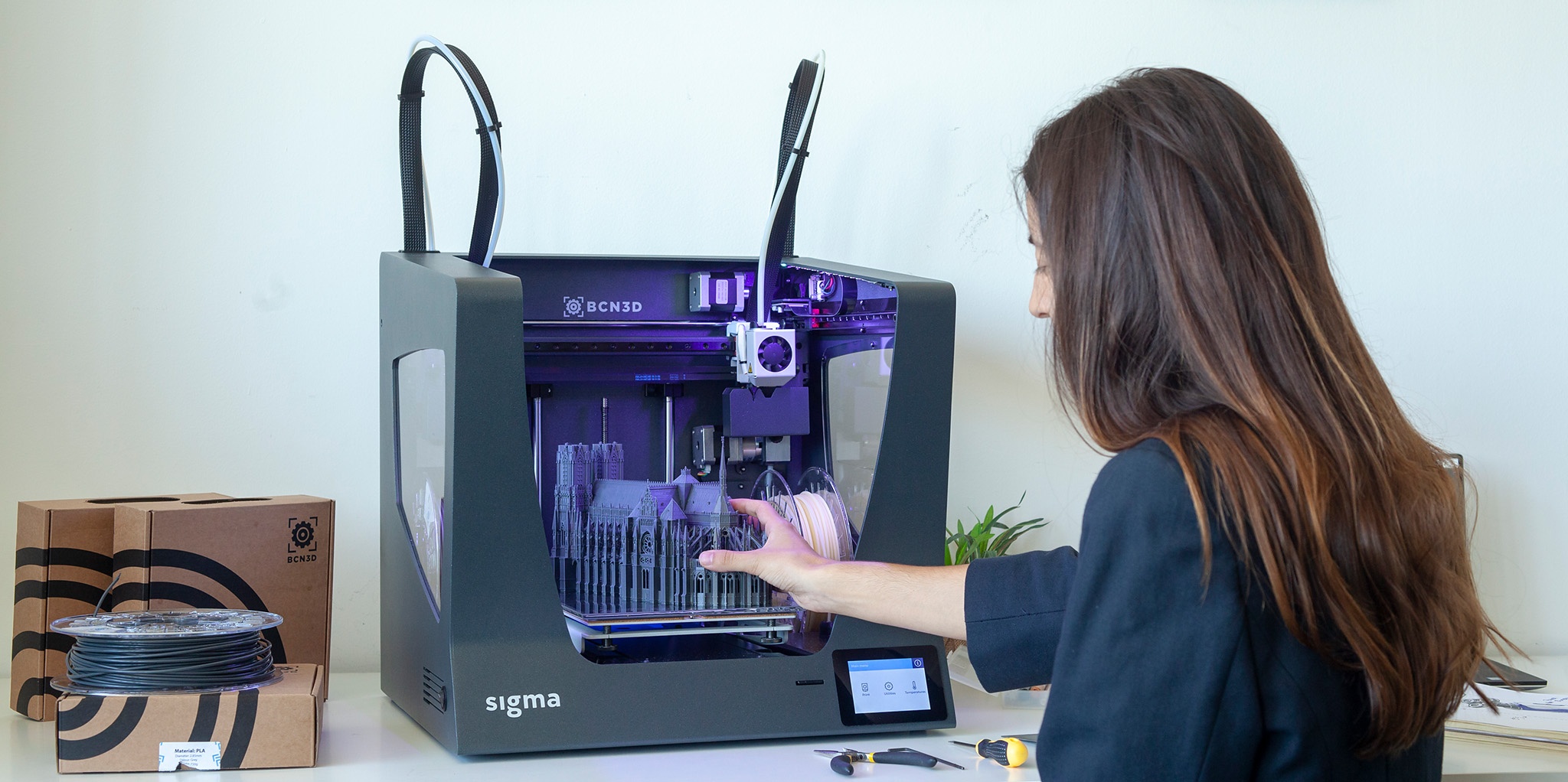

Open filament system, unlimited versatility

With its optimized full metal hotends the Sigma can print any material you need to fit your requirements, from the common PLA to the most advanced technical plastics like Nylon or PC, independently the manufacturer.

A new standard

A new standard